If you need your TPR Not sure about your ability to change, you can call a plumber. There is always the possibility that something goes wrong, so if you are not sure that you will be able to do it properly, it is possible to hire a professional for you. Is the best When the cost is very good, it is better to accidentally damage your water heater or injure yourself than to replace something as simple as a pressure relief valve India. There is no shame in finding the easy way out, we just want to make sure the work goes well. What is hydraulic fracturing?

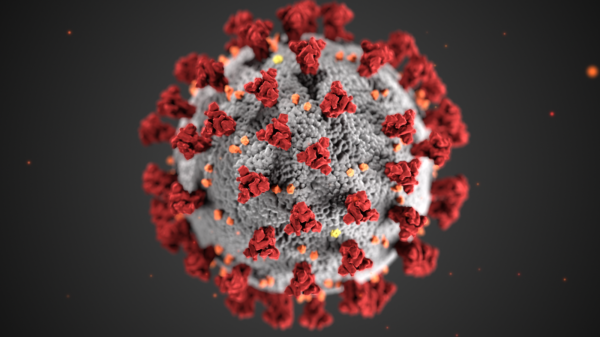

In the Australia, hydraulic fracturing is a common method used to release natural gas from reserves thousands of feet below the earth’s surface. This method is also called fracking. As part of this special method, millions of gallons of water, special chemicals and sand are injected into groundwater wells by ground wells that have been specifically drilled for fracking. This joint pressure acts on layers of rock, creating cracks in them. Naturally produced gas comes out of this man-made crash and floats to the surface through the well. This gas is then transported to the storage tank and further processed. The processed gas is then delivered to the market.

Why is a fracking valve important for this process?

The well that is drilled to the lake can move 10,000 feet below 10,000 feet to 10,000 feet above the earth’s surface. Needless to say, the pressure required for the formation of hydro-chemical-sand mixtures in such cold places is tremendous. A powerful pumping system is required for this purpose. Where high pressure comes into play, a powerful and effective pressure relief system is also needed. Thus, the fracture valve helps to control the pressure level of the pumping system.

In the absence of proper pressure relief systems, large-scale pumps and pumping systems can cause irreversible damage. In addition to the pressure relief valve, the emergency shut valve is just as important.

Over the past two decades, many industries have moved beyond the use of conventional rupture disks or Pressure Relief Valve Manufacturers, and have chosen fracture valves with broken pins. These valves are more effective and very reliable. They have the ability to withstand huge losses. The best thing about a valve with a cramped pin is that it can be used even with pulsed pressure! Typically pump type pumps have a heartbeat, where the pressure increases rapidly or increases with the set pressure level. Pulsation pressure is thought to be the cause of wear between devices and systems.

What are some properties of a quality fracking valve?

When it comes to hydraulic fracturing, a torn pin-based pressure relief valve or an emergency shut valve can be used instead of a nitrogen assisted valve or ball / spring reset valve. This is ideal if your chosen freak valve can relieve freak fluid for pressure in the range of 7,000psi to 15,000psi.

Soil and slurry relief valves are types of pressure relief valves that are widely used in various industries. The original purpose of the valve is to relieve pressure from the construction of mud or slurry during drilling operations. Discharge of any type of fluid on the valve piston, seal or seat can relieve excess pressure within a few milliseconds.

The relief valve pin is made using the compressor column’s Euler’s Law. This means that they can handle intense pressure spikes and beats while maintaining certain pressure relief. The mud relief valve can be fitted to remove pressure between 500 and 6,000 psi.

Components of the valve

Some parts are used to make valves. The basic components to publish when assembled are:

- The body of the valve

- Seat cage

- Piston

- Crash Seal

- Brake pin

- The structure

The mud relief valve is designed to reduce pressure at a certain pressure rate. When the pressure begins to increase, it acts on the piston area, and a large amount of axial force exerts pressure on the pin. When the set pressure rate is reached, the pin buckles and the valve open. Within a few milliseconds, the pressure is immediately released. This helps protect other pressure components such as pumps, hoses and the overall slurry system.

As sludge valves can be set at different pressure rates, different rupture pins are designed to meet each pressure setting. The buckling stress of the pin is higher than the yield stress. The biggest feature is its simplicity. The pin can only be changed by removing the pin nut and replacing the pin. For this reason, rupture pins are seen as an important part of engineering and an important component of the ground relief valve.

You must be logged in to post a comment Login